KEY INNOVATIONS

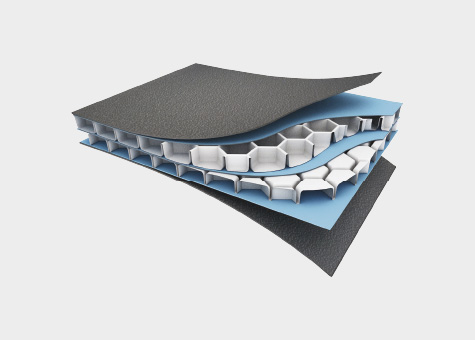

ALVEOLAR CORE LAYER , ENDLESS POSSIBILITIES

Our leading-edge technology allows to equip the line with several different alveolar matrixes, thus matching speciflc market requirements.

- Hexagonal/honeycomb bubbie

- Conical

- Linear

- Etc.

Each one of these is available in different matrixes and sizes thus permitting outstanding ranging parameters in one machine only (200 + 6000 gsm).

BUBBLEGUARD® BOARD FACTS & FIGURES

Web width: up to 2200 m;

Extrusion dies: up to 5 units;

Extruders: up to 8 units;

Min. gsm: 200;

Max. gsm: 5000;

Min. thickness: 1.3 mm;

Max. thickness: 30 mm;

Lamination with outer/inner fabrics or films: up to 4 units with double shaft;

Thermoforming calenders: 1 or 2;

Thermoforming cylinder matrix: Negative, Positive, Positive/Negative.